In the realm of advanced materials science, aerogel metamaterials have emerged as a revolutionary solution for extreme thermal insulation. These nanostructured wonders defy conventional limitations, creating an invisible shield against temperatures ranging from cryogenic -100°C to blistering 3000°C. Unlike traditional insulation materials that rely on bulk or density, aerogels achieve their remarkable properties through carefully engineered nanoscale architectures.

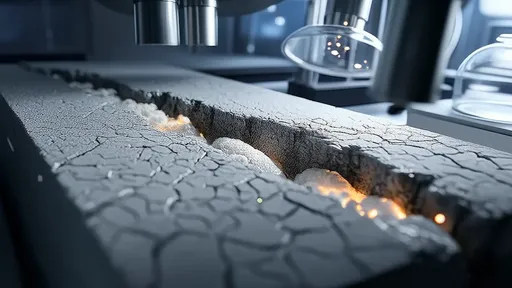

The secret lies in their mesoporous structure – a delicate three-dimensional network where air constitutes over 90% of the volume. This intricate matrix of nanopores and nanofibers creates what physicists call the "Knudsen effect," where gas molecules collide more frequently with pore walls than with each other, effectively stifling heat transfer. Researchers have recently pushed these boundaries further by developing hybrid aerogel composites reinforced with ceramic nanofibers and graphene oxide sheets.

Space exploration agencies have been particularly enthusiastic adopters of this technology. The Mars rover missions utilized aerogel-based thermal protection systems to safeguard sensitive instrumentation from the planet's dramatic temperature swings. During lunar expeditions, these materials prevent heat from seeping into cryogenic fuel tanks while simultaneously shielding equipment from solar radiation. Engineers report that just a 10mm aerogel layer provides better insulation than 50mm of conventional ceramic fiber blankets under extreme conditions.

Industrial applications are undergoing quiet transformation as well. In energy-intensive sectors like metallurgy and glass manufacturing, aerogel panels now line furnace walls, reducing heat loss by up to 70% compared to traditional refractory bricks. The chemical processing industry benefits from their corrosion resistance when insulating pipes carrying molten salts or superheated steam. Even more remarkably, certain aerogel formulations maintain structural integrity after direct exposure to oxyacetylene flames exceeding 2000°C for prolonged periods.

The manufacturing breakthrough came with the development of ambient-pressure drying techniques, eliminating the need for complex supercritical drying processes that previously limited production scale. Material scientists have also perfected controlled pyrolysis methods to create carbon-based aerogels with graded density profiles – denser layers facing extreme heat sources transitioning to more porous structures toward cooler surfaces. This biomimetic approach, inspired by thermal regulation in deep-sea vent organisms, allows for unprecedented thermal gradient management.

Beyond industrial applications, consumer products are beginning to incorporate thin aerogel membranes. High-performance outdoor gear now features flexible aerogel composites that provide warmth without bulk, while electric vehicle battery packs utilize flame-retardant variants for thermal runaway prevention. Architects experiment with translucent aerogel panels that offer both insulation and diffuse daylighting, potentially revolutionizing energy-efficient building envelopes.

Recent military applications demonstrate the material's versatility. Specialized aerogel coatings protect sensitive electronics from electromagnetic pulse effects while providing thermal stealth capabilities. Naval engineers incorporate these materials into submarine hull designs for both acoustic damping and thermal signature reduction. The material's low density makes it particularly attractive for aerospace applications where weight savings are critical.

Looking toward future developments, researchers are exploring dynamic aerogels that can alter their thermal properties in response to electrical stimuli or pH changes. Another promising avenue involves self-healing aerogel composites that can repair minor structural damage caused by thermal cycling. As production costs continue to decrease, these remarkable materials may soon become commonplace in applications ranging from household appliances to interplanetary spacecraft, silently guarding against temperature extremes that would challenge most other substances known to science.

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025