The construction industry is undergoing a quiet revolution with the emergence of self-healing concrete, a groundbreaking material that promises to extend the lifespan of infrastructure while reducing maintenance costs. At the heart of this innovation lies an unlikely hero: microorganisms capable of repairing cracks autonomously. This bio-concrete represents a paradigm shift in how we think about building materials, blending biology with engineering to create structures that can literally heal themselves.

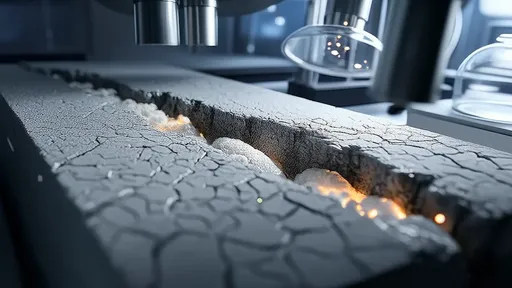

Traditional concrete, despite its strength and durability, is prone to cracking over time due to environmental stresses, chemical attacks, and mechanical loads. These cracks, often microscopic at first, allow water and aggressive chemicals to penetrate, eventually leading to corrosion of reinforcement steel and structural deterioration. For decades, engineers have sought solutions to this fundamental weakness, but it wasn't until researchers looked to nature for inspiration that a truly transformative approach emerged.

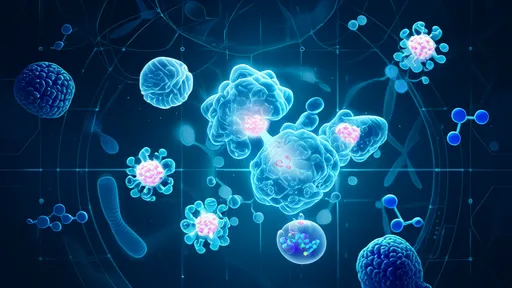

The science behind microbial self-healing concrete is as fascinating as it is effective. Scientists embed specially selected bacteria spores and their nutrient source (often calcium lactate) into the concrete mix during production. These microorganisms remain dormant until cracks form and water infiltrates the material. When activated by moisture, the bacteria begin to metabolize their food source, producing limestone as a byproduct that gradually fills the cracks from the inside out.

What makes this process particularly remarkable is its precision and efficiency. The bacteria only activate when needed - when cracks appear and water is present - meaning they can remain viable for decades before springing into action. The healing process typically begins within days of crack formation and can completely seal fractures up to 0.8mm wide, significantly improving the concrete's durability and waterproofing capabilities.

Several bacterial strains have shown particular promise for this application. Bacillus pseudofirmus and Sporosarcina pasteurii are among the most commonly used species due to their ability to survive in concrete's highly alkaline environment and their efficient production of calcium carbonate. These extremophile bacteria naturally thrive in harsh conditions, making them perfectly suited for life within concrete structures.

The implications of this technology extend far beyond simple crack repair. By preventing water penetration, microbial concrete significantly reduces the risk of steel reinforcement corrosion - the primary cause of structural failure in concrete buildings and bridges. This could dramatically extend the service life of critical infrastructure while reducing the need for costly repairs and the associated carbon emissions from construction activities.

Field tests and early applications have demonstrated the technology's real-world potential. In the Netherlands, a municipal parking garage became the first structure to incorporate self-healing concrete on a large scale. After several years of service, microscopic analysis revealed that bacterial activity had successfully sealed developing cracks, validating the concept outside laboratory conditions. Similar pilot projects are now underway in Japan, the United Kingdom, and the United States.

Environmental benefits represent another compelling advantage of microbial concrete. The global construction industry accounts for approximately 8% of total CO2 emissions, with cement production alone responsible for a significant portion. By extending structure lifespans and reducing the need for replacement concrete, self-healing technology could make a meaningful contribution to sustainability efforts in the built environment.

Challenges remain before widespread adoption becomes feasible. Current formulations add about 10-15% to material costs, though proponents argue this premium is offset by long-term savings. Researchers are also working to optimize the concentration and distribution of bacteria within the concrete matrix while ensuring the microorganisms remain viable throughout the structure's intended lifespan, which could span centuries for some infrastructure projects.

The development of self-healing concrete illustrates how interdisciplinary collaboration can yield transformative solutions. Microbiologists, materials scientists, and civil engineers have combined their expertise to create what might be the first widely adopted "living" building material. As research progresses, future iterations may incorporate different microbial strains capable of performing additional functions, such as air purification or pollution absorption.

Looking ahead, the integration of microbial concrete with other smart material technologies could lead to even more advanced infrastructure systems. Imagine buildings that not only repair themselves but also adapt to environmental changes or generate energy through biological processes. While such visions remain in the realm of research, the successful development of self-healing concrete proves that biological solutions can work in construction environments.

As climate change increases the stresses on our infrastructure through more extreme weather patterns, the need for resilient building materials becomes ever more pressing. Microbial self-healing concrete offers a promising path forward - one where structures gain biological attributes that help them withstand the test of time. This innovation stands as a testament to human ingenuity and our growing ability to harness nature's solutions for technological advancement.

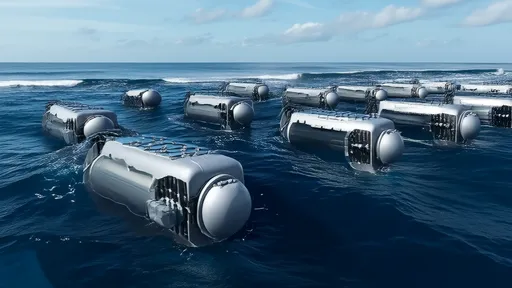

The coming decade will likely see increased commercialization of this technology as production scales up and costs decrease. Early adopters are already specifying microbial concrete for critical infrastructure elements where repair would be particularly difficult or costly, such as underground foundations, bridge decks, and offshore structures. As performance data accumulates from these real-world applications, confidence in the technology will grow, potentially making self-healing capabilities a standard feature in future concrete formulations.

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025